PA/PE Thermoforming Film

Products Description

PA/PE Thermoforming film is primarily a plastic film that is heated to applicable forming temperatures, thus achieving the desired shape.The outer layer is made of PA, which has high tensile strength, impact strength, toughness, and good transparency. It also has a good and stable friction coefficient and anti-puncture effect. It is suitable for packaging in high-speed vacuum packaging machines.

QiluVac PA/PE vacuum packaging thermoforming film produced by down blowing water quenched process technology, for seafood packaging applications.

Products Features

Products Application

QiluVac thermoforming film is ideal for a variety of food and non-food products, such as seafood(Salmon, Fish, Crab, shrimp), sausage, meat, poultry, soft or hard cheese and dairy products, bakery products, ready meals (burger, pizza, eggs), and medical devices (infusion/IV bags, syringes, surgical items).

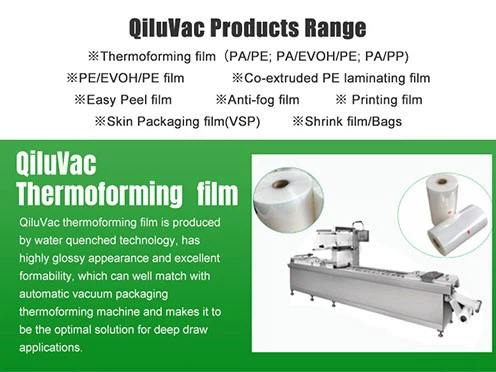

QiluVac Products Range

Products Packaging Details

Our packaging can be:

1)With bubble film packaging, followed by pallet wrapping;

2)With Carton packaging, followed by pallet wrapping.

3)We can customize packaging and LOGO according to customer requirements.

Packaging Process

Loading Container

Products Quality Control

Strict quality control procedures are implemented in every link from raw material storage to finished product delivery. We have professional OTR and WTR testing equipment to ensure product quality at the source.

Company Profile

Shandong Qilu Ethylene Chemicals Co., Ltd(Brand: QiluVac). was established in 1987, covering an area of 300 acres and employee more than 400 people. QiluVac currently has 6 fully automatic food packaging film production lines with an annual output of 15,000 tons. QiluVac is a Shandong High-Tech enterprise and has got ISO9001 Certificate, ISO22000 Food Safety Management Standard and FDA Report. QiluVac is committed to providing customers with best materials and green packaging solutions.

37

years

Our company was founded in 1987.

6

production lines

We have 6 production lines, with 15000 tons capacity per year.

18

awards

We have won a lot of awards for strong creativity.

Company Culture

Our Company Culture

why choose us

why choose our Company?

1)Good Reputation.

Founded in 1987, with more than 30 years experience, good reputation;

2)Professional technical support.

Professional technical team and customized packaging solutions;

3)Fast delivery time.

Siz production lines with an annual output of 15000ton with fast delivery time;

4)Quality Guarantee.

ISO, FDA and SGS, all materials are in compliance with FDA Contact Legislation.

FAQ

Q1: What are the main materials of your food packaging film?

A1: Our food packaging film is mainly made of polyethylene (PE), polypropylene (PP), EVOH and other materials, which are non-toxic, harmless, odorless, highly transparent and high barrier.

Q2: What are the specifications and sizes of your food packaging film?

A2: We provide food packaging films of various specifications and sizes, including different thicknesses, widths and lengths, which can be customized according to the specific needs of customers.

Q3: How to use food packaging film correctly for food packaging?

A3: When using food packaging film for food packaging, the food should be cleaned first, and then the packaging film should be laid flat on the operating table, the food should be placed in the center of the film, and the packaging film should be folded or heat-sealed as needed to ensure that the food is completely wrapped and well sealed.

Q4: What should be paid attention to during the use of food packaging film?

A4: During use, the food packaging film should be prevented from being scratched or torn by sharp objects. At the same time, keep the packaging film clean and dry to avoid contact with harmful substances.

Q5: What should I do if the food packaging film I purchased has quality problems?

A5: If the food packaging film you purchased has quality problems, please contact our customer service staff immediately. We will handle it for you as soon as possible and provide corresponding after-sales services, including return, exchange, etc.

Q6: Does your food packaging film support customization?

A6: Yes, we support customized services for food packaging films, and can customize materials, specifications, sizes, printing, etc. according to the specific needs of customers.

Q7: Has your factory passed relevant certifications?

A7: Yes, our factory has passed ISO9001 quality management system certification, IS022000 Food Safety Management System certification and other relevant certifications to ensure product quality and safety.

Hot Tags: pa/pe thermoforming film, China, suppliers, manufacturers, factory, buy, price, for sale, made in China, Bottom Film for Sausage Package, High Barrier Packaging Film, Skin Packaging Film, PP Retort Film, High Barrier Thermoforming Film, EVOH High Barrier Film